Matoorka stator khadka tooska ah

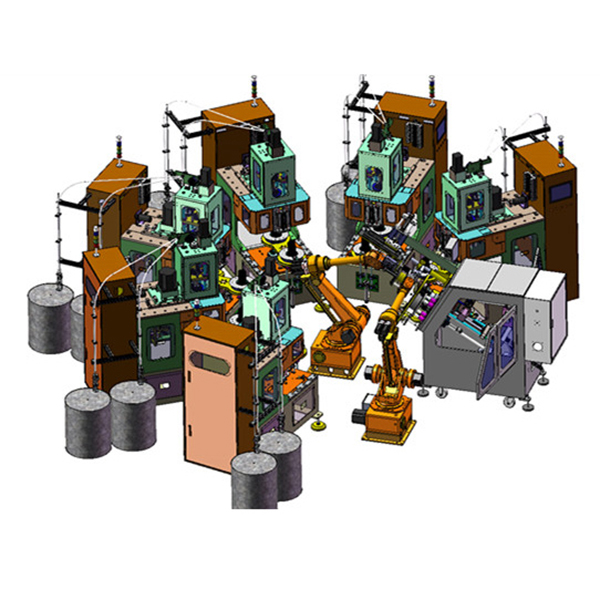

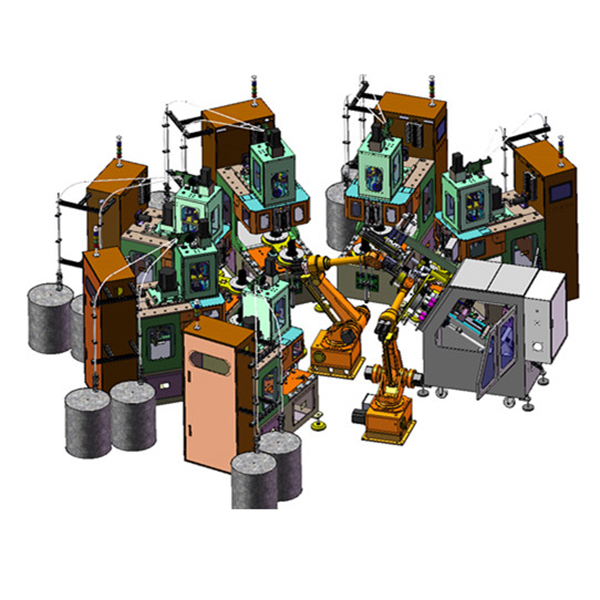

Sharaxaada Alaabta

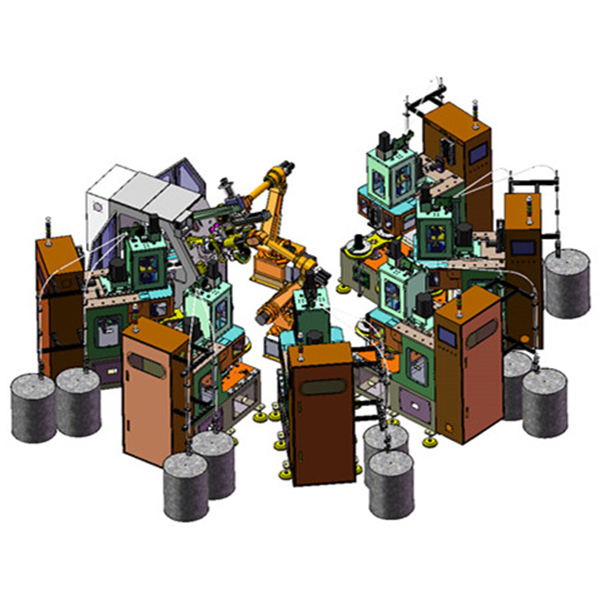

● Robot-ka waxaa loo isticmaalaa in lagu wareejiyo gariiradda mashiinka dabaylaha toosan iyo mishiinka gelinta siliga servo ee caadiga ah.

● Badbaadinta shaqada shaqada ee dabaylaha iyo galinta fiilooyinka.

Qaab dhismeedka

Xallinta dhibaatooyinka caadiga ah ka dib kulanka khadka tooska ah ee rotor

Isku-xidhka khadka tooska ah ee rotor-ka waa qalab toos ah oo ka kooban hawl-wadeenno, walxaha dareemayaasha, iyo kontaroolayaasha.Cilada ku jirta khadka isku xirka tooska ah ee rotor-ka ayaa keeni kara qallafsan ama gabi ahaanba qalliin aan shaqaynayn.Maqaalkan, waxaan kaga hadlaynaa afar hab oo caadi ah oo lagu garto cilladaha ku jira khadadka isku xirka rotor-ka tooska ah.

1. Samee kormeer dhamaystiran oo ku saabsan sahayda korantada, isha hawada, iyo qalabka hawo-biyoodka ee isku xirka khadka tooska ah ee rotor.Inta badan dhibaatooyinka khadka isku xirka tooska ah ee rotor-ka waxay ka yimaadaan dhibaatooyinka sahayda korantada, isha hawada iyo isha hawo-mareenka.Markaad hubinayso, hubso in korontada ku jirta aqoon-is-weydaarsiga ay ku filan tahay iyo in dhammaan qalabku si caadi ah u shidman yahay.Fiiri isha cadaadiska hawada iyo bamka hawo-qabeenka ee looga baahan yahay haydarooliga khadka.

2. Hubi in booska dareemaha ee isku xirka khadka tooska ah ee rotor uu isbedelay.Waqti ka dib, dareemayaasha ayaa laga yaabaa inay la kulmaan arrimo xasaasi ah, cillad, ama beddelka booska.Booska ogaanshaha iyo dareenka dareemaha waa in si joogto ah loo hubiyaa, si sax ah loo hagaajiyaa marka boosku isbeddelo, oo isla markiiba la beddelo marka uu guuldareysto.Dhibaatooyinka gariirka inta lagu jiro dhaqdhaqaaqa dhaqdhaqaaqa khadka isku xirka rotor ayaa sidoo kale sababi kara dareemayaal dabacsan.Waa muhiim in la xaqiijiyo in dareemaha uu si adag u jiro.

3. Hubi gudbinta, waalka kantaroolka socodka iyo waalka kantaroolka cadaadiska.Shaqada soo-gudbintu waxay la mid tahay tan dareemaha induction magnetic, iyo dhibaatooyinka dhulka muddada-dheer waxay saameyn doonaan isticmaalka caadiga ah ee wareegga waxayna u baahan yihiin in la beddelo.Nidaamka pneumatic-ka ama hawooroliga ee khadka isku-xidhka, furitaanka waalka ceejinta, guga hagaajinta cadaadiska ee waalka cadaadiska, iwm. waxay lumin doontaa adkaanta ama simbiriirinta dhibaatooyinka gariirka, waxayna u baahan yihiin dayactir joogto ah inta lagu jiro isticmaalka caadiga ah.

4. Hubi isku xirka korantada, pneumatic-ka iyo hayirida.Haddii hubinta goobta cilladdu aysan muujinin meesha ay dhibaatada ka timid, hubi heerka wareegga aaladda wareegga furan.Hubi in kirishbooyada siliggu aanay ahayn kuwo qaabaysan sababo la xidhiidha ka bixista oo ka baadh bronchus wixii waxyeelo ah ama laalaabtay.Hubi haddii wareegga saliidda hadhidarooliga uu xanniban yahay.Haddii hawo-mareenku si daran u laalaabtay, waa in isla markiiba la beddelaa.Haddii ay dhibaato ka jirto tuubada saliidda ee haydarooliga, waxay sidoo kale u baahan doontaa in la beddelo.

5. Haddii shuruudaha kor ku xusan aysan jirin, suurtagalnimada dhibaatooyinka barnaamijka ee kontoroolka khadka tooska ah ee rotor waa mid hooseeya.